A sublimation printer is a special type of printer designed to print full-color, long-lasting images onto various surfaces, most commonly fabrics, ceramics, metals, and plastics.

The term “sublimation” refers to the process in which a solid is directly transformed into a gas without going through a liquid phase. In sublimation printing, the printer heats the dye and directly transfers it from the solid state to the substrate, thereby generating high-quality full-color images.

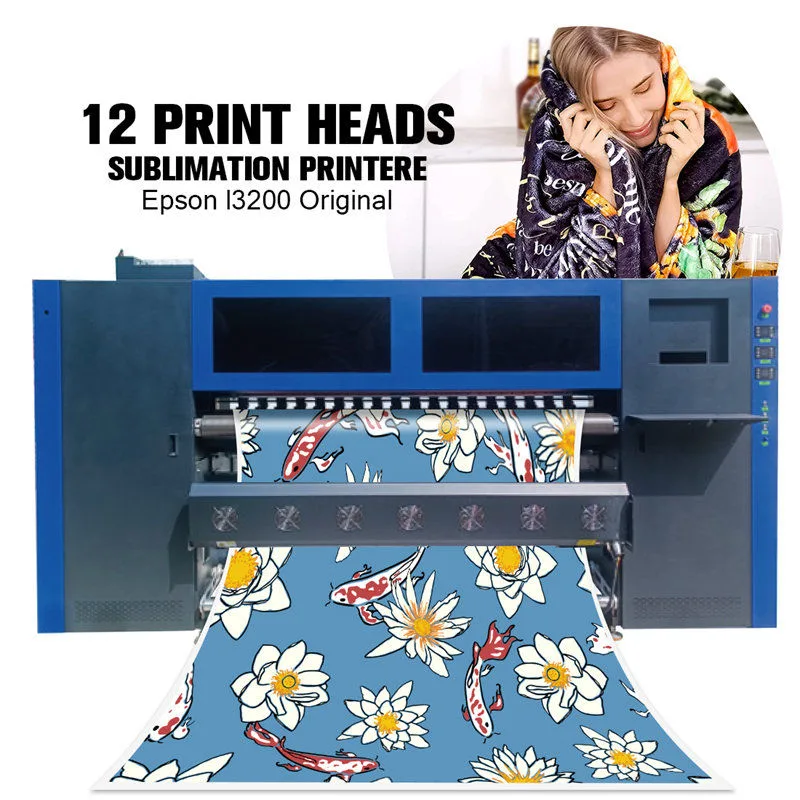

Sublimation printing is a unique process. The design is first completed on a computer and then printed on special transfer paper using sublimation ink. Ink is solid at room temperature, but it turns into gas when heated. The function of a sublimation printer is to precisely print sublimation ink onto transfer paper in the form of high-quality images.

Then place the printed pattern on the transfer paper and print it onto the surface of the object carrying the image. Sublimation printing is most commonly used on polyester fibers or other items treated with polymer layers, such as mugs, T-shirts, and phone cases, because these materials are crucial for the chemical bond between the dye and the base fiber.

The paper and items are then subjected to a short period of high heat (usually around 30 seconds to 1 minute, depending on the material and item size), typically between 175°C and 225°C.

High temperature causes the dye to sublimate, changing the ink from solid to gas. This gas will penetrate the surface of the material, combine with the fibers, or form a coating at the molecular level. As the object cools down, the dye will re-solidify into a solid state, effectively embedding the image onto the surface.

One of the greatest advantages of sublimation printing is its high image quality, bright colors, and long-lasting durability. Because the dye is closely combined with the fabric or material, the printed images will not crack, peel off, or fade over time, making it very suitable for high-usage products such as custom T-shirts, mugs, and banners.

Sublimation printing can also achieve designs with rich colors and layers. It can easily replicate fine color schemes without the need for separate processes or special settings as in screen printing. This makes it particularly suitable for the production of specific custom patterns in small and large batches or extremely fine and multi-colored patterns.

In addition, compared with other printing techniques, this process is more environmentally friendly because the sublimation ink is water-based and the transfer paper can be recycled. This printing method generates the least waste and does not use toxic chemicals or solvents, thereby significantly reducing the harm to users and the environment.

Although sublimation printing has many advantages, it also has some limitations. It is only applicable to certain specific materials, such as polyester fibers or materials with polymer coatings. Natural fibers such as cotton have poor adhesion to sublimation ink, which limits their versatility in certain projects. This might be a drawback for those who want to print on various fabrics.

Initial investment is another limiting factor. Compared with traditional inkjet printers or laser printers, sublimation printers and their related equipment (such as heat presses) are expensive. In addition, special sublimation inks and transfer paper will increase costs, which may make this method less feasible for small-scale or ordinary users.

For any business or enthusiast who wants to create top-notch custom works with outstanding and long-lasting printing effects, a sublimation printer is an essential tool. It can directly transfer ink onto materials, thereby achieving excellent color reproduction and durability. If you are looking to invest in professional and high-quality printing solutions, then sublimation printing is an excellent choice, offering precision and reliability.